3D Manufacturing: Shaping the Future to Come

Posted in Future, Futurist, Manufacturing

(Editor’s note: The following is an excerpt from my forthcoming book, 20/20 Vision: 20 Trends Which Will Transform Business in the Coming Decade, that I am writing with the able assistance of fellow futurist Simon Anderson, host of www.futur1st.com. This chapter covers trends in the emerging field of 3D manufacturing.)

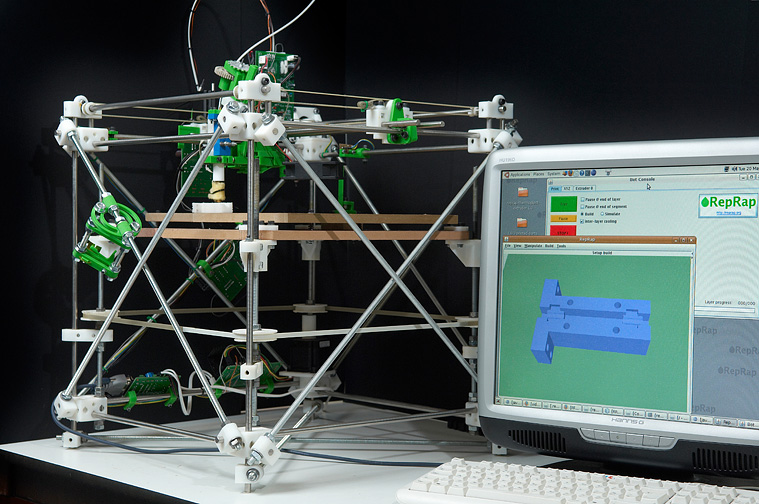

In a non-descript lab in the mechanical engineering department at the University of Bath in England sits a device as revolutionary as Gutenberg’s printing press. The device, dubbed RepRap, is a rapid prototype manufacturer–a 3D printer–that can print physical objects. What makes RepRap so unusual and potentially transformative is that it can print many of its own components. And while RepRap cannot yet print every part of itself, it is not difficult to imagine a day in the not-too-distant future when it will be able to achieve such an extraordinary feat.

The field of 3-D printing is quickly advancing and in the coming decade it will transform the manufacturing sector and the larger global economy in some surprising and unexpected ways. To better grasp the potential of this technology let’s peak in on Kim, a young Canadian artisan living in Toronto.

During her morning jog along the Humber River, Kim notices an interesting flower growing around a small tree and it inspires her with an idea for a new necklace design to add to her growing line of customized jewelry. When she gets back to her apartment studio, Kim, who taught herself jewelry design using a course on the popular “College-At-Home” software, sketches the design freehand in her notebook. After making a few tweaks, she unfolds her flexible computer tablet and scans the design into a sophisticated software program which suggests a few modifications and renders the drawing into a three-dimensional model. From her computer, Kim then projects the drawing into a holographic form and rotates it with a haptic glove so she can view it from all angles. Kim accepts all of the computer’s suggested changes and adds a few of her own in an effort to further improve upon the design.

The task of physically printing the first draft of necklace takes only a few minutes in spite of the fact that it incorporates a series of small interlocking pieces that appear to have been assembled by hand, but which are, in reality, printed simultaneously. Such a complicated design would have been impossible to produce even a few years earlier, but with the extraordinary developments in 3D printing–which is referred to as ‘additive manufacturing” in Canada–Kim feels as though she is on the cutting edge of a previously unimagined field of art and design–and she is.

Kim regularly meets with other “fabbers” in Toronto to share, discuss and “hack” designs. Some of her colleagues are designing and printing entirely unique musical instruments, while innovative engineers are using the technology to design new motors that require no lubricants and will be more reliable because they can be printed already fully assembled to exacting specifications. Still others are experimenting with printing more complex electronics and even batteries. As one fellow “fabber” said recently, “This technology is like having a factory at your house!” There is one thing that they all agree on: 3D manufacturing is allowing artisans and engineers to by-pass old constraints and other “form versus function” trade-offs and instead bring to life previously impossible designs.

After physically inspecting the initial prototype, Kim returns to her computer and makes a few quick modifications to her design. Satisfied, she could upload the design into the same $99 printer she used to create the first version but opts to employ her top of line 3D printer because it can utilize cartridges of titanium–her material of choice for this necklace. Kim then hits a print button and the 3D printer in her living room whirrs into action and, layer-by-layer, it prints her necklace. By mid-afternoon the jewelry is complete. Even though she has done this many times lately, Kim still shakes her head in wonder. Only hours earlier the necklace had been nothing but a vision and now she was holding the physical manifest of her idea.

In year’s past, Kim would have uploaded the design directly to her website–where it would have holographicly rotated for the viewing pleasure of admirers and potential buyers–and begun selling the final product. Unfortunately, there has recently been a rapid increase in the number of 3D “pirates” who have taken to stealing her and other people’s original designs and selling the pirated work at a substantial discount. In an effort to combat the problem, Kim has taken the precautionary measure of creating and printing her designs with a unique mix of printable electronic coding tags and unique nanomaterials–both of which serve to authenticate her work. These additions have allowed Kim to continue to market and sell her work to high-end customers, but she knows a great many people can’t tell the difference between an original and a counterfeit piece of her work. Indeed, even she has a problem spotting the difference herself.

As someone who grew up listening to pirated music Kim realizes counterfeiting is just the way of the world now. So, when she reflects on all the ways 3D manufacturing has improved her life, she has a difficult time getting too upset about the occasional design being copied. Only the day before, she learned she needed to have a crown on a molar replaced. The entire process, which only a few years earlier would have cost $800 and taken a return trip to the dentist to complete, was finished in less than 30 minutes at a fraction of the old cost because the dentist could simply scan her tooth and print a perfect fitting replacement in just one attempt. In recent weeks, Kim has also printed a new pair of designer shoes for herself as well as a customized action figure of Canada’s most recent gold medal Olympic figure-skating champion for her seven year-old niece, which she downloaded for a small fee, after viewing a digital advertisement on a subway station billboard.

The same technology has also allowed Kim to keep her vintage 1964 Ford Mustang running smoothly for years. For instance, when her engine blew a gasket earlier in the year she was able to download the design for the part and print it out in less than 15 minutes. Kim remembers the old days when finding any old spare part would have set off a time-consuming search for a supplier who still manufactured it and taken a great deal of money and the better part of three days to receive the part after she finally located it. Now she just visits the “Classics” section of Ford’s website and downloads virtually any replaceable part on her car for a fraction of the cost. This reason alone could easily justify her purchase of a 3D printer!

The real reason Kim is so pleased with additive manufacturing, however, is because of what it has meant for her loved ones. Her boyfriend, a special forces soldier in the Canadian army, is alive today because after a search-and-destroy robot he was using to defuse bombs in eastern Africa was debilitated by a fast exploding incendiary device, his unit was able to swiftly get the robot operational again using a portable 3D printer that was able to manufacture all of the necessary components on location. Later that day, the robot successfully detected a cleverly hidden roadside bomb.

Similar 3D printing technology has also dramatically improved the life of Kim’s mother. After using her smartphone to detect melanoma, a surgeon was able to remove the cancerous lesion and replace it with a swath of biocompatible skin which was printed out using her mother’s own stem cells. The only way the new printable skin could be distinguished from the surrounding skin was that it looked slightly smoother and younger.

Kim is optimistic that just as 3D printing can keep her 1964 Mustang running for the foreseeable future, the technology will also be able to do the same for her mom–who was born in 1944–by soon being able to print other body replacement parts, including kidneys, liver, lungs and, eventually, even a functioning heart.

On the issue of whether this vision of printable human organs ever comes to fruition, Kim is less optimistic than she is about her car parts always being available. Recently, members of the Conservative Party in Canada have introduced legislation seeking to severely limit the uses of 3D printing technology. While concerns over the technology’s impact on the longevity of its citizens is an issue (experts warn that the technology could increase life expectancy 5 to 10 years), the more pressing concern is what 3D printing technology has done to the Canadian manufacturing and transportation shipping sectors. Whereas before 3D printing’s rapid rise, more than 1.5 million Canadians were employed in traditional manufacturing and supply chain distribution jobs, that number has plummeted since 2015.

Kim and many of her peers in the emerging class of new entrepreneurs (who are now profitably employed by utilizing 3D printing technology) have countered that the technology is also creating jobs, but the labor unions representing the traditional tool-and-die workers as well as FedEx and UPS workers who have lost their jobs–and who have little else to do these days but protest–have waged a successful public relations battle in the media and appear to be swaying public opinion in their direction. Also joining in to oppose the technology have been police and law enforcement groups that are concerned over how criminal groups are using the technology to print high-quality Glock handguns.

Kim shares the police’s concern (but has printed a handgun for her own safety) and understands the frustration of the traditional manufacturers and shippers but believes these workers are modern-day Don Quixote’s and are tilting against windmills. She can’t imagine Canada or any other country in the world returning to yesteryears outdated and inefficient manufacturing methods and models. “Why,” Kim asks opponents of 3D manufacturing, “is using vast amounts of raw materials to produce millions of parts which have to be produced in places such as Canada, India and China and then be shipped around the world, a superior model to allowing individuals the freedom and luxury of being able to print out exactly what they need, when they need it, at a fraction of the cost and ecological footprint?”

Kim is still waiting to hear a good response but, not content to just let the future takes its course, she returns to her apartment and prints out a new shirt with the slogan, “The Revolution Will Be Printed.”

Interested in reading about another coming trend by futurists Jack Uldrich and Simon Anderson? Check out this recent piece on gaming dynamics: